Introduction

Industrial cleaning is a crucial part of maintaining efficiency, safety, and product quality. Traditional cleaning methods, including chemical solvents, abrasive blasting, or manual scrubbing, can be time-consuming, damaging, and environmentally harmful. Dry ice cleaning machines offer a revolutionary alternative, providing efficient, non-abrasive, and chemical-free cleaning across multiple industries. This guide explains how dry ice cleaning machines work, their benefits, applications, and tips for safe and effective use.

What is a Dry Ice Cleaning Machine?

A dry ice cleaning machine, also known as a CO2 blasting machine, uses compressed air to accelerate small pellets of dry ice (solid carbon dioxide) onto a surface. These pellets remove contaminants such as oil, grease, adhesives, paint, and carbon buildup. Unlike sandblasting or chemical cleaning, dry ice cleaning does not damage the underlying surface and leaves no secondary waste.

How Dry Ice Cleaning Works

The cleaning process combines three main effects:

1. Kinetic Energy Impact

Dry ice pellets strike the surface at high speed, dislodging dirt, grease, and paint.

2. Thermal Shock

The extremely low temperature of dry ice (-78.5°C) causes contaminants to contract and crack, making them easier to remove.

3. Sublimation

Dry ice sublimates on contact, turning directly from solid to gas. This eliminates secondary waste, unlike sand or chemical cleaners.

This combination makes dry ice cleaning suitable for delicate machinery, electrical components, and food processing equipment.

Benefits of Dry Ice Cleaning Machines

Non-abrasive Cleaning

Dry ice cleaning is gentle on surfaces, making it ideal for molds, conveyor belts, electrical panels, and other sensitive equipment.

Chemical-Free Cleaning

No chemicals are needed, reducing environmental impact and eliminating the risk of contaminating products.

Reduced Downtime

Dry ice cleaning can often be performed without stopping production lines, saving time and increasing productivity.

Versatility

It effectively removes grease, oil, paint, adhesives, and carbon from metal, plastic, rubber, and glass surfaces.

Applications of Dry Ice Cleaning Machines

Food Industry

Ideal for ovens, mixers, and conveyor belts, dry ice cleaning removes baked-on food residue, grease, and fat without chemicals, ensuring compliance with food safety regulations.

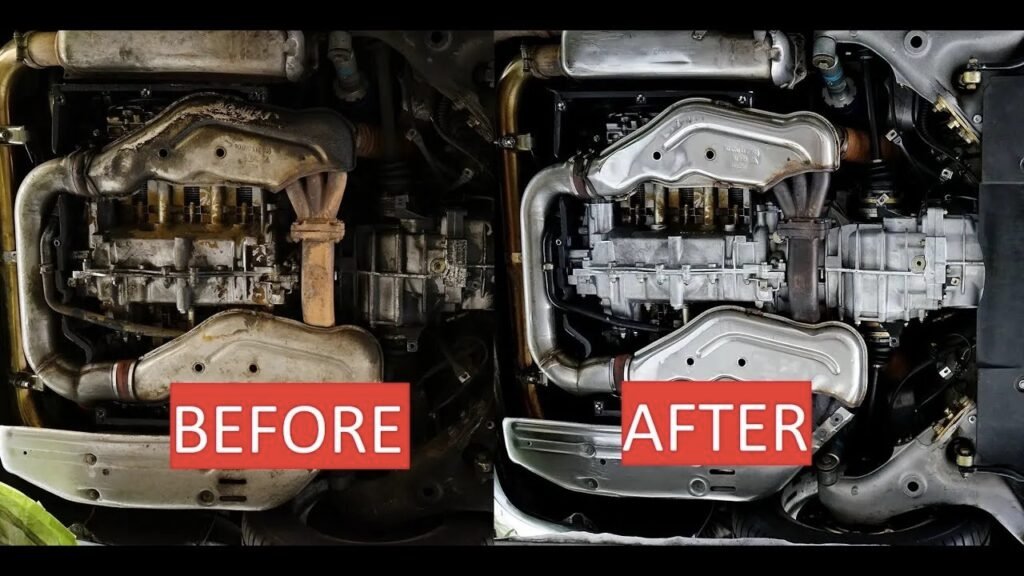

Automotive and Aerospace

Engines, molds, and aircraft components can be cleaned efficiently without damaging precision parts.

Manufacturing and Printing

Dry ice cleaning removes carbon buildup, ink, and adhesives from molds, printing presses, and electronics, reducing maintenance time.

Restoration and Maintenance

Historic buildings, monuments, and delicate machinery can be cleaned without abrasive damage, preserving original surfaces.

Choosing the Right Dry Ice Cleaning Machine

Factors to consider when selecting a dry ice cleaning machine include:

- Nozzle Type – Precision nozzles for delicate surfaces, wide nozzles for large areas.

- Pellet Size – Fine pellets for sensitive equipment, larger pellets for heavy-duty cleaning.

- Air Pressure and Flow – Adjustable settings ensure optimal cleaning without surface damage.

- Mobility – Portable units suit multiple locations; stationary units are ideal for large-scale operations.

Safety Considerations

Although dry ice cleaning is generally safe, following precautions is essential:

- Wear protective gloves and goggles to prevent frostbite.

- Ensure proper ventilation to avoid CO2 buildup.

- Maintain equipment regularly to prevent malfunctions.

Maintenance Tips

- Regular Inspection – Check hoses, nozzles, and air compressors.

- Clean After Use – Remove moisture to prevent clogs.

- Follow Manufacturer Guidelines – Adhere to recommended service schedules.

Proper maintenance ensures consistent performance and longevity of the dry ice cleaning machine.

Conclusion

Dry ice cleaning machines provide a non-abrasive, chemical-free, and efficient solution for industrial cleaning. Suitable for food processing, automotive, aerospace, manufacturing, and restoration, these machines reduce downtime, improve equipment longevity, and maintain high cleanliness standards. By adopting a dry ice cleaning machine, businesses can achieve faster, safer, and more environmentally friendly cleaning processes.